![]() 400-850-1759

400-850-1759![]() China

China

![]() 400-850-1759

400-850-1759![]() China

China

Yanmao Intelligent Equipment (Suzhou) Co., Ltd.

Contact: Ren Hongbing

Mobile: 18016000798

Landline: 0512-53635091

Fax: 0512-53635090

QQ: 18016000798

Website: m.kawaiiland.cn

Address: No.8, Xingsheng Industrial Park, 11 Xingye South Road, Taicang City, Jiangsu Province

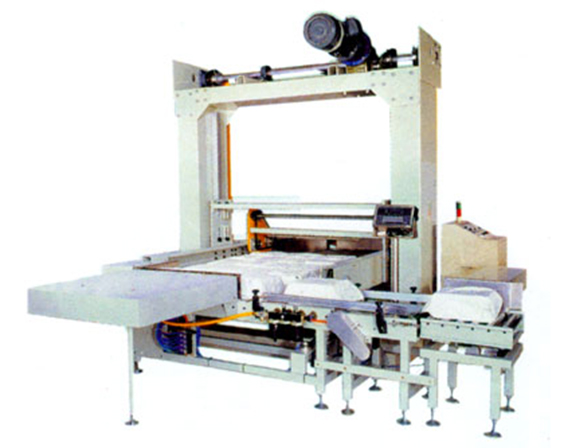

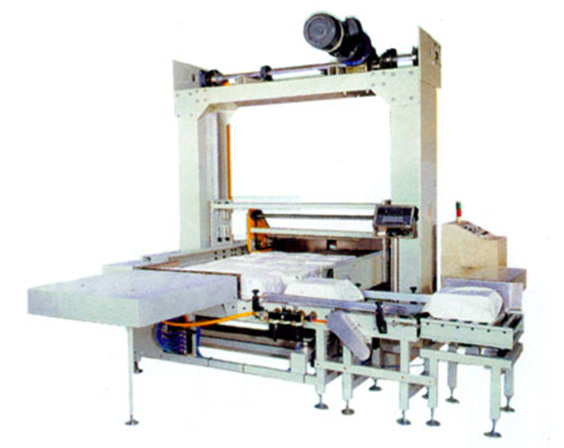

Sacks of fertilizer, flour, cement and other powdery materials are usually packed in automatic weighing, packaging and stitching. Usually through the material lifting equipment or from the silo to the weighing equipment, electronic weighing equipment according to pre-set to complete the automatic weighing process, and the material into the packaging equipment, packaging. Packaged materials through checkweigher weight re-inspection, unqualified packaging will be automatically removed, Checkweigher also can provide feedback signal to the weighing equipment, adjust the checkweighing settings. The metal detector can be installed before the material enters the packaging machine and after the packaging is completed, in order to detect the presence or absence of metal foreign matter mixed into the product. In line with the standard packaging Coding, plastic, transportation, palletizing, winding, until sent, the whole process using computer PLC management, packaging automation. Will be based on the specific product of different, combined with the different needs of users for users of the packaging line design.

★ Touch screen operation to achieve man-machine dialogue, can show the production speed, cause of the malfunction and location, high degree of automation. Using PLC programmable carton sorting stacking layer, pallet supply and discharge can be programmed into the program control.

★ Japan's CMC produced by the chain with good wear resistance, high precision, stable transmission and so on.

★ Germany FESTO or Taiwan CHELIC, Japan's SMC pneumatic components and cylinders, quality, reliable performance.

★ safety door, hood equipped with electrical induction device, when the cover door is opened, the machine stops working, personnel can be protected.

★ stack adjustment easy, simple, can be carried out on the touch screen. Stacking stable, efficient, can greatly save manpower.

★ Carton supply system uses brake motor control, to ensure that the pre-set position of the delivery of cardboard boxes

★ large capacity pallets, can accommodate 12-15 empty pallets, pallet can be automatically supplied.

★ motor (motor), reducer are used Nordic Germany products.

★ Do not need to change the stacking parts to complete several stacking methods.

According to the actual site conditions and product features, we can make low palletizers for you. High palletizers; Servo palletizers; Robotic palletizers; Depalletizers

machine type | XKMD-03 | XKMD-04 |

Power / Power | 380V 50/60HZ 3.5KW | 380V 50/60HZ 4.5KW |

Suitable for pallets | L1200*W1200mm | L1200*W1200mm |

Stacking speed | 10-20Package / minute | 15-30Package / minute |

Stacking height | 小于2000mm | 小于2000mm |

Machine size | 7300*4100*3300mm | 9000*4100*3300mm |